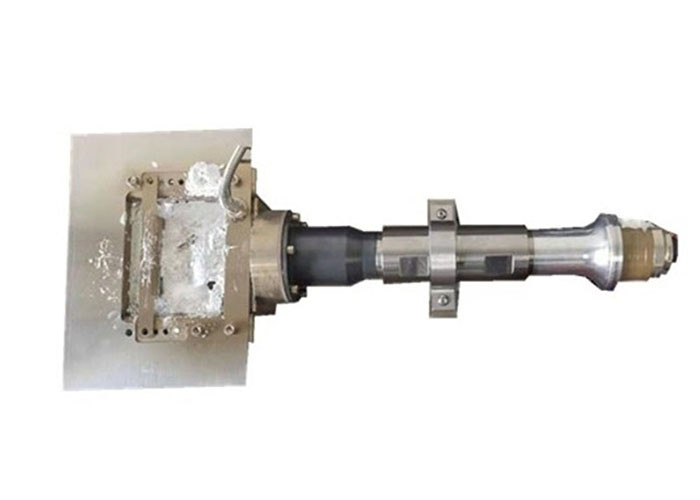

20Khz Environmentally Friendly Ultrasonic Tin Plating Technology

Description:

Ultrasonic tin soldering treatment is the process of applying

ultrasonic waves to liquid tin material, generating cavitation

effect. This effect is used to destroy and remove the oxide film on

the surface of the base material, allowing the liquid tin material

to wet the surface of the base material. The ultrasonic welding

tool head is applied to a position far away from the solder joint.

Firstly, the tin material and base material are heated to the

soldering temperature using a heating coil. Then, ultrasonic

vibrations greater than 20 kHz are transmitted to the base material

through an ultrasonic tool head, with an amplitude range of 0-100 μ

mm and a vibration time of 0.5-10 seconds. After the vibration is

completed, the base material is allowed to cool naturally. The

significant feature of ultrasonic wave tin plating is the

low-temperature solder bonding.

Parameters:

| Model | FST-2020-GL |

| Name | 20Khz Ultrasonic Dip Soldering Equipment

|

| Frequency | 20Khz |

| Power | 2000w |

| Input Voltage | 220V±10%,50/60Hz |

| Working Mode | Intermittent or Continuous working |

| Temperature Range | 200 -400℃ |

| Application | Tin, Indium, Silver, Copper, Nickel, Aluminum Wires. |

Advantages :

1. Green and environmentally friendly

Ultrasonic immersion welding has the characteristics of safety and

environmental protection, and does not require the use of harmful

compounds such as substances that remove oxide films. When

performing immersion welding, no flux is used, and there is no need

for emission facilities or wastewater treatment facilities to

remove harmful gases generated by the use of flux. Therefore, there

will be no harmful chemicals produced to the environment and human

health.

2. Cost savings

There is no need for pre-treatment or washing processes before

ultrasonic immersion welding, which can save production costs and

simplify the welding immersion process and improve production

efficiency. No process related to soldering flux is required, thus

reducing equipment and production costs. At the same time, due to

the lack of processes related to soldering flux, the soldering

process is simple (high soldering productivity).

3. Support the development of new applications

Ultrasonic immersion welding can successfully weld materials that

are traditionally difficult to weld, such as glass and ceramics.

Suitable for solar cell glass, semiconductors, ceramic heaters, and

heterogeneous materials (Al copper, aluminum glass, aluminum

ceramics).

4. Direct processing

Ultrasonic immersion welding can directly heat tin blocks without

the need for pre-treatment. In addition, the parts can be directly

immersed in a tin pot for tin plating operation.

20Khz Environmentally Friendly Ultrasonic Tin Plating Technology